Prior to joining Autodesk, he worked as a CAE engineer for several companies in the automotive industry. As the Experimental Solvers feature is still being developed and improved, it is available as a preview feature. This means that to use it, you will need to enable it in the Preferences dialog box of Fusion 360. To do this, first open the Preferences window by choosing the Preferences option (4) inside the menu (3) in the upper right corner of the Fusion 360 window.

Try generative design in Fusion 360

Please assume that all posts are [serious] by default, and try to respond with serious comments if at all possible. Some funny feedback is welcome, but it shouldn't overwhelm the serious comments on the thread. The expectation is that people come here to learn new techniques or solve a problem, frequently for their job. Consider a part that is additively manufactured to start with (as per our example). You’ll also be able to use the Fusion 360 modelling and CAM tools to develop jigs/fixtures to carry out those inevitable post-build machining cycles, such as facing off mating faces, thread or other operations. When using any of these results inspection methods, it’s possible to both dive into the results individually or select up to four for close comparison.

Which product would you like to try?

We’ve also added tools for helping you select the best outcome and have improved our geometry conversion to make using an outcome in your design process increasingly more seamless. You may have also noticed in-product surveys, experiments and promotions around our pricing model to learn what works best for you. We’ve refined our usage of cloud computing, significantly increasing our efficiency through better alignment with how you’re using the solution. On the other hand, we have generative design in Fusion 360 software—the technology that revolutionizes the engineering world and the ways we design things.

Let's get started

Furthermore, AI is also making significant impacts within design and development areas. AI-powered tools can simulate and test various design scenarios in a fraction of the time it would take humans to do manually. An example might be using AI to simulate the stress and strain on various materials, helping designers to select the most durable choices for their products. By identifying potential issues early in the development cycle, AI helps to accelerate the design process and improve final product quality. A primary benefit of AI is its ability to analyze large datasets quickly and accurately.

Explore Technology Topics

He also completed postgraduate studies in software development methodologies. He joined Autodesk in 2016, and is currently working as a senior software engineer. He's been involved in generative design from the beginning of this project and is based in Krakow, Poland. Krystian Motawa graduated with a master’s degree in Structural Engineering. He’s been involved in generative design from the beginning of this project and is based in Krakow, Poland.

Accelerate your product development process

To use Generative Design, you need to work in the Generative Design workspace, which you can access from the Workspace menu list.

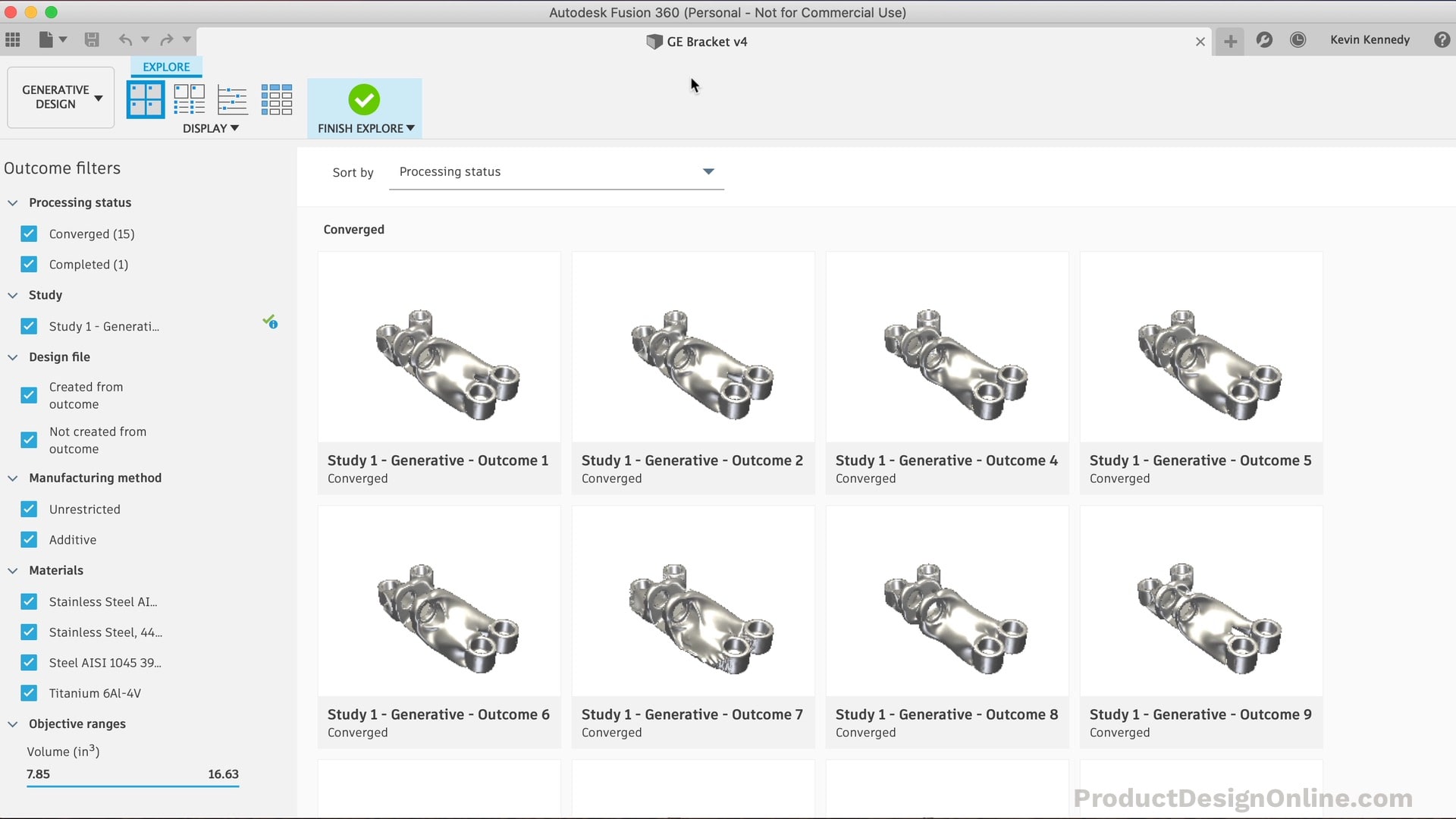

You have a range of tools to do some basic inspection of results, but chances are that you’ll want to take these further. It’s here that having these tools built into a full-featured modelling and manufacturing system like Fusion 360 comes into its own. The comparison environment allows you to have up to four concepts on screen at once, with synchronised views and inspect tools, ranging from standard pan/zoom/rotate, to display of stresses on the parts, design space ghosting, and more. By default, this shows you factor of safety versus mass, where each study is plotted against those axes, but these can be switched to whatever properties you’d like on each of the axes. This will take a quick scan of your job and generate a pretty rough optimisation domain for your studies as a greyed-out lump of geometry. This gives you a very quick sanity check, indicating the direction your studies might take and possibly flagging up any glaring errors.

Generative design, by contrast, allows you to work without an explicit domain – and this is fundamental. In theory, this is all you need to do for the system to handle the creation of the domain for optimisation – but that’s a rather gross oversimplification. With Experimental Solvers and Features, we can gain more control by constraining allowable displacements. As the preview option is turned on, the additional options appear in Objectives and Limits.

For this study, we are currently recruiting people with mechanical design experience and familiarity with at least one major CAD tool (Autodesk Inventor/Fusion, Solidworks, OnShape, etc.). This area of learning content consists of a series of tutorials that provide you with detailed, step-by-step instructions for a variety of different tasks, and are a great way to get started with the Generative Design in Fusion. This is where, in Fusion 360, you incur more cost, because to export concepts is going to cost you 100 cloud credits.

10 Fusion 360 Classes to Attend at Autodesk University 2023 - Autodesk Redshift

10 Fusion 360 Classes to Attend at Autodesk University 2023.

Posted: Wed, 23 Aug 2023 07:00:00 GMT [source]

Access an expanding repository of generative design resources to help inspire new ideas. Participants will be invited to participate in up to two study sessions (one being 90 minutes and the other 45 minutes long). During these sessions, participants will receive a design brief to work on. After completing the design task, participants are invited to join a post-study interview with the research team.

This can be created either with or without an intact construction history and can then be taken through further workflows and validation, and eventually, perhaps, into production. Combined with the filters and grouping/colouring options, you can very quickly gain an understanding of how your experiments are progressing or have completed and where they lie on the performance front. With these, you can just about define the parameters of your machine tool capability.

In the context of manufacturing, this capability is crucial for identifying trends, predicting outcomes, and making data-driven decisions. AI plays an important role in making manufacturing processes streamlined with its ability to catch errors that are often overlooked by humans. For example, computer vision AI systems can detect minute defects in materials or inconsistencies in production processes. AI’s ability to enhance these processes results in higher quality control, sustainability, and process optimization across the manufacturing line. Generative design has been enabling companies to overcome some of their hardest engineering challenges. It helps improve the performance of your product by light-weighting or improving structural integrity, while giving you the freedom to explore more design and manufacturing alternatives some of which go beyond human imagination.

Starting today, we’re making generative design subscriptions accessible at a game-changing price point of $200 USD per month. Generative design in Autodesk Fusion 360 made its initial commercial debut in October of 2018. Since then, we’ve been learning a lot about how we can make it easier for you to try what we believe will be beneficially transformative to the way you design and engineer your products.

AI integration promotes proactive supply chain management, maintaining manufacturing processes even in unforeseen circumstances. Yes, the generative design technology does carry out a cursory simulation using your load cases, but this won’t be enough to validate whether these hyper-optimised forms can withstand real-world loading conditions. At this point in our workflow, we now have a shortlist of concepts from the generative design process that have both completed and converged. Each computation is iterative in nature (typically resolving in around 25 iterations).

No comments:

Post a Comment